Industrial IoT – Manage and Control Remote Assets

-

This is a guest post by Florian Hoenigschmid, Director of azeti. If you would like to contribute a guest post, please contact [email protected]

When you make a phone call, watch TV or wash your hands, you probably won’t associate this with terms like predictive maintenance, equipment damage, downtime or Service Level Agreements initially.

However, those things are helping to provide services such as mobile connectivity, a stable power grid or clean water. IoT gateways running asset management applications, connected to sensors and machinery are part of a remote asset management system, which monitors and controls critical infrastructure like generators, compressors or HVAC systems in remote locations such as cell towers, water pumping stations or secondary substations. These systems provide operators with insights about the performance of their assets in remote locations. This helps to determine if an asset is about to stop working and therefore require maintenance (preventive maintenance), if equipment has been stolen/destroyed or if operations could be improved and organized in a more cost effective way. The installed remote asset management systems help to minimize downtime, which in turn means a higher quality of the service provided.

Full Stack – Ubuntu and azeti

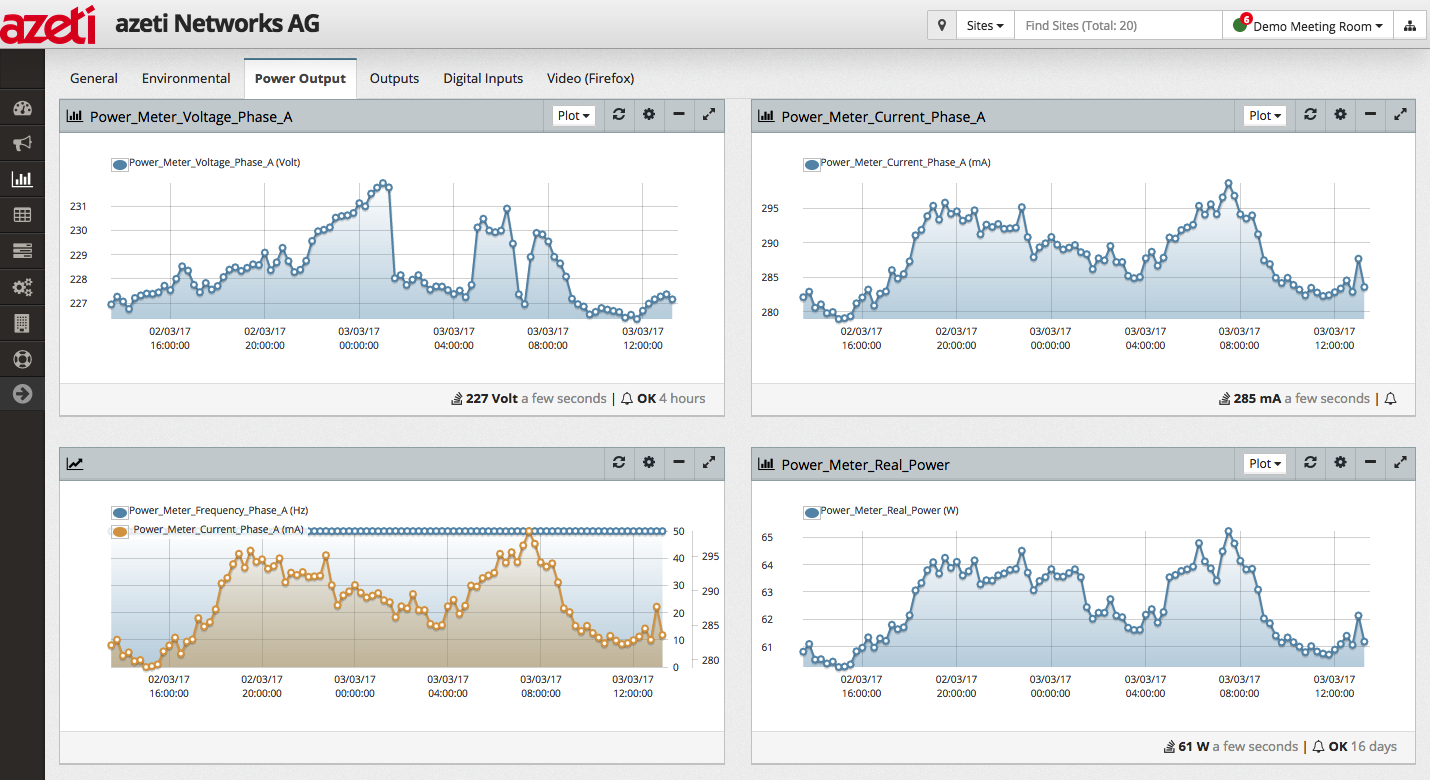

azeti’s solution is the full stack for managing industrial environments consisting of intelligent software for the edge (azeti Site Controller) running on IoT gateways plus a central server (azeti Engine) application providing visualization, management and deployment capabilities.Ubuntu Core is the solid fundament for the IoT application and eliminates worries about OS upgrades, security updates and general OS management for thousands of devices. Its broad gateway support helps to choose the right hardware depending on customer’s requirement without a hardware vendor lock-in.

Edge Intelligence for Harsh Environments

azeti’s Site Controller is comparable to a virtual PLC (programmable logic controller) and provides interfaces for all prominent sensor protocols plus sophisticated analytics and automation. This local intelligence enables independence from the network uplink, as even without a cloud connection all local rulesets and automations will function.If a couple years ago, the paradigm was to centralize, process and analyze everything in the cloud, azeti and Canonical are demonstrating that this paradigm is now shifting towards the edge of the network. As all the data is processed right where it is generated by sensors and machinery, the need for bandwidth and therefore costs is reduced, local execution of action lowers latency and a network with distributed computing also decreases its vulnerability compared to a centralized approach, which may create a single point of failure.

Reference Use Cases

Remote Maintenance Service for Electric Drives – a great example of how IoT can generate new revenue and optimize operations is the project with one of the largest electrical drives vendors where azeti provides the software stack to collect metrics from the drives and visualizes those in beautiful dashboards. Customer can now check health and performance of their drives in a modern web application without connecting directly to the machinery. Remote maintenance is now offered as a new service by the vendor; the increased visibility into assets allow sophisticated preparation before engineers are sent on site, downtimes are decreased and maintenance efforts are reduced. Customers receive better service and increased uptimes of their environments.

Battery and Generator Management in the Jungle – another real life deployment is with a service provider customer that operates several hundred telecommunication sites in demanding locations such as close to the coast or in deep jungles. The major requirement was to allow remote health checks of their on-site batteries as well as remote maintenance work for the diesel generators. Network uplink is unreliable and visits to the sites have to be reduced as much as possible. azeti’s automation engine gathers performance and health data from installed sensors and directly from the machinery. The operations team can now remotely discharge and charge the batteries, start and stop the generators and gain insights of the whole facility. On top of this, video cameras provide live feeds and access control eliminate the necessity for physical keys. On site visits and maintenance efforts have been tremendously reduced as periodic charging and discharging cycles increase the batteries lifetime heavily and diesel generators are started and stopped on a regular basis to ensure stable operations during times of outages. One of these outages just happened recently during a hurricane where the solution proved its solidness.

Further use cases in logistics, manufacturing, utilities and medical logistics show the variety of IoT solutions – Ubuntu Core for IoT is the layer enabling all the use cases and applications, hardware agnostic, security and easy manageability.

Learn more about azeti here.

https://insights.ubuntu.com/2017/04/17/industrial-iot-manage-and-control-remote-assets/

© Lightnetics 2024